What is TTR Cable?

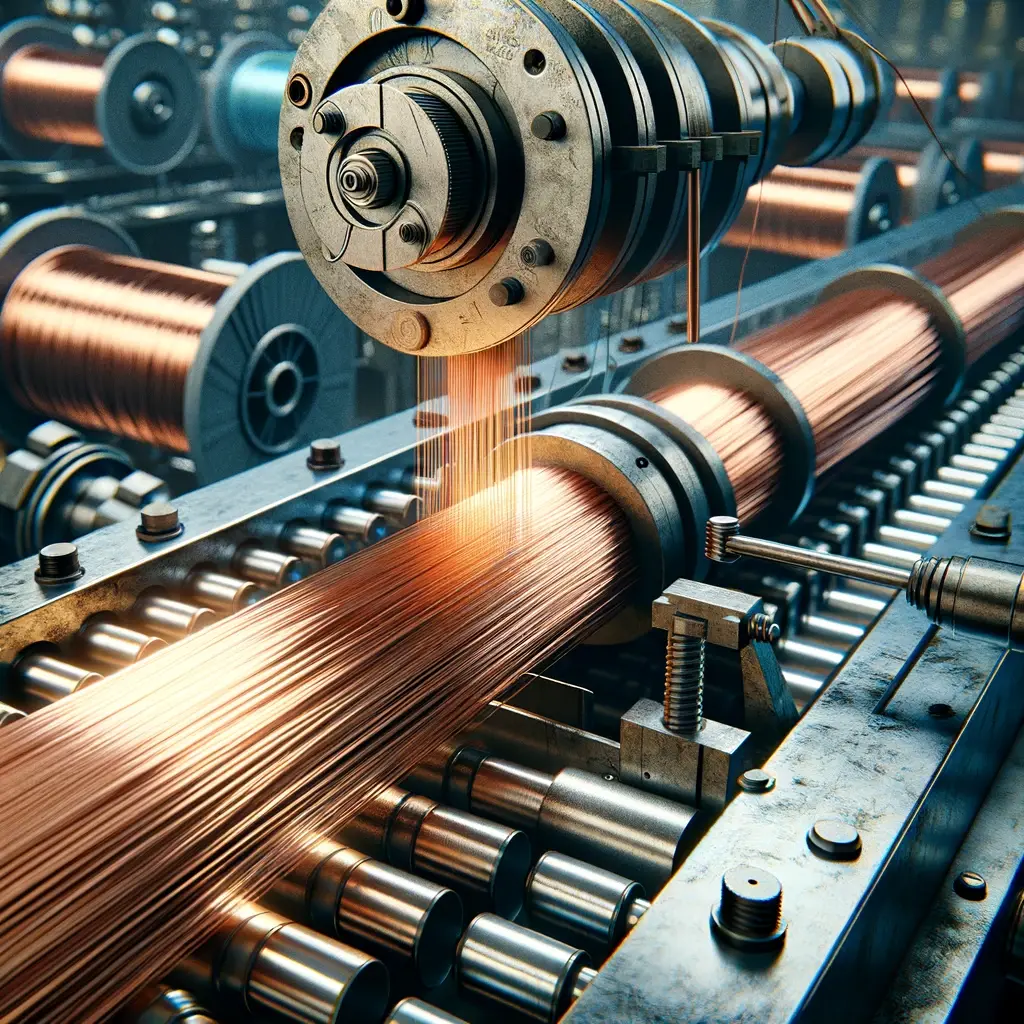

Cable types vary based on their application areas. Therefore, the characteristics of the cable also change depending on where it will be used. The question “What is TTR cable?” naturally comes to the forefront at this point. It would not be an exaggeration to say that we see TTR cables everywhere we turn in our homes. Externally, TTR cables are PVC-coated and made from thin copper wire. Thanks to their PVC insulation, TTR cables offer safe usage and are typically found in household items. For TTR cables to be used in an electrical installation, mechanical stress should be kept to a minimum.

TTR Cable Prices and Types

TTR cables are classified according to the number of wires they contain and the cross-sectional area of these wires. For instance, a TTR cable with a 1.5 mm cross-section and two conductors is referred to in the industry as a “2×1.5 TTR cable.” Similarly, TTR cables with three conductors and a 1.5 mm cross-section are known as “3×1.5 TTR cables.” Among the most commonly used TTR cable types by electricians are 2×1.5 TTR cable, 3×1.5 TTR cable, 3×2.5 TTR cable, and 4×4 TTR cable. The number of conductors within the cable also indicates the cable’s durability. In TTR cable types expressed as 2x, the grounding conductor, also known as the grounding wire, is not included within the cable. It is important to choose the cable considering safety and TTR cable current carrying capacities.

When examining TTR cable prices on the market, it is clear that the price varies depending on the PVC material used and the different materials in its internal design. Additionally, the length of the TTR cable and the number of conductors it contains are factors that affect the price. It is advisable to purchase these cables in longer lengths whenever possible to reduce the unit cost per meter.

TTR Cable Features & Current Carrying Capacities

TTR cables, which have flexible usage areas, are widely used in the electrical sector. The material, which should be of appropriate cross-section depending on the application areas, is generally used as an extension cable in electrical installations that will not experience mechanical stress, in wet and humid areas, in places where additions to the installation are necessary, in lighting installations that are not part of the main electrical installation, and in the internal mechanisms of electronic devices and the cables that power them. The features of TTR cables should be selected according to the area of use. When determining the cross-section of a TTR cable, the length of the cable and the power of the current to be drawn should be considered. The best way to decide on this is by knowing the current carrying capacity of the TTR cable. The high number of conductors in the cable provides a significant advantage in terms of safety and efficiency. The current carrying capacity of TTR cables ranges from 3-32 A, depending on the material and the number of conductors used in the cable. Antigron cable is also referred to as “NYM cable.”

NYM cable models are mainly used in industrial areas and in places with fire and explosion risks, where additional protection is not needed. In this context, NYM cables can be safely used in wet and humid environments, provided they are not exposed to sunlight. It can be said that the price of NYM cables is relatively higher compared to TTR cables. The difference between Antigron and TTR cables stems from the differences in their application areas and prices. Another type of cable, NYA cable, is also commonly used in factories, workshops, and their warehouses where there is a risk of fire and explosion. NYA cables can be used both on and under plaster.